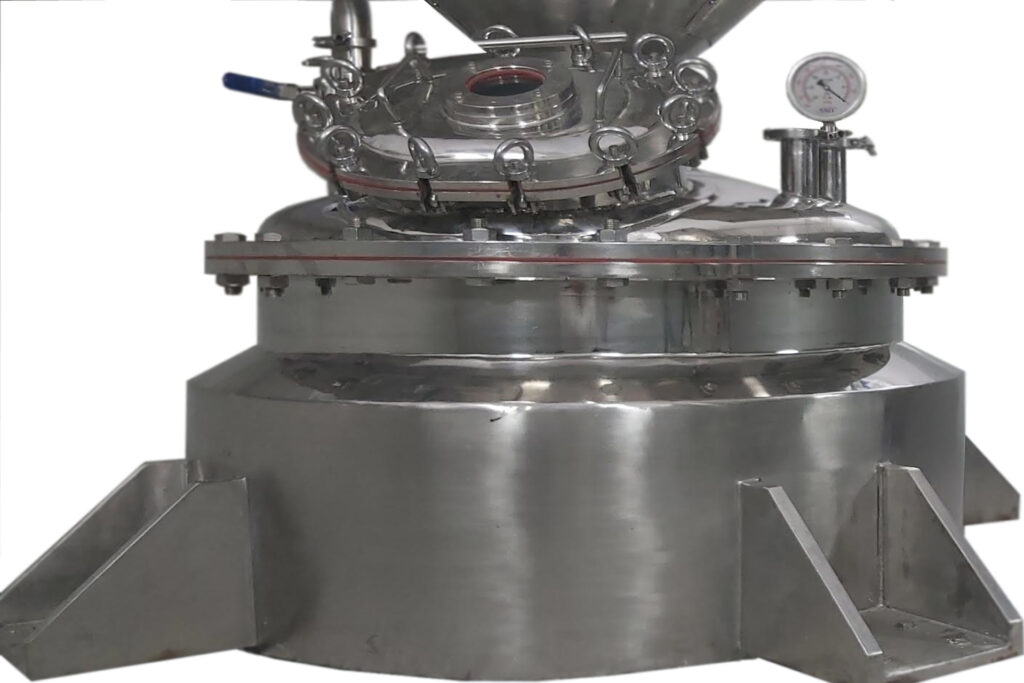

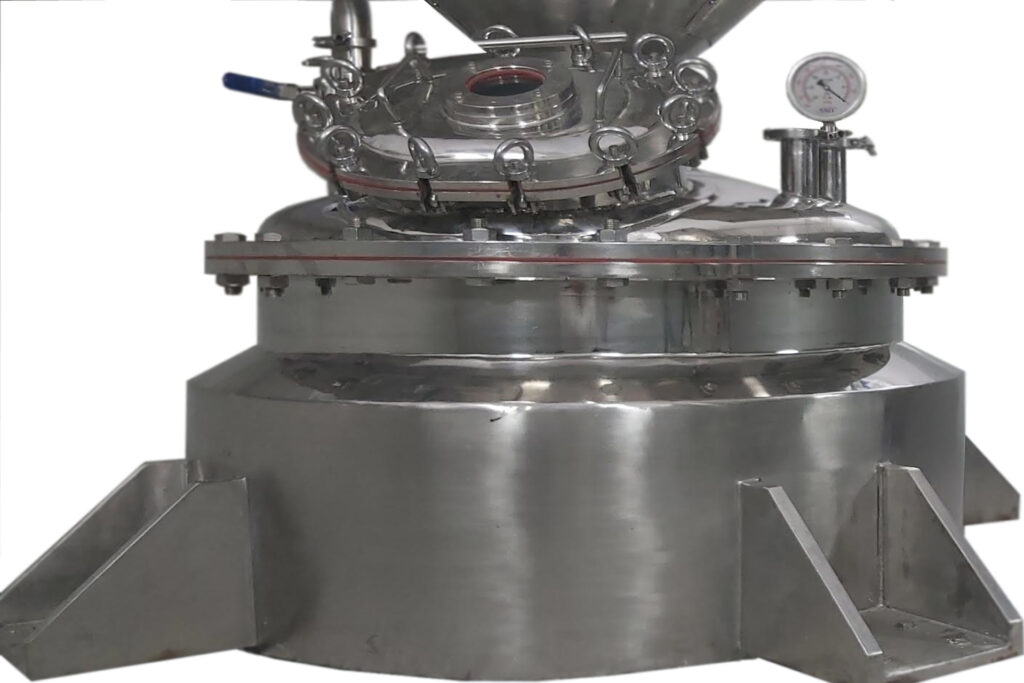

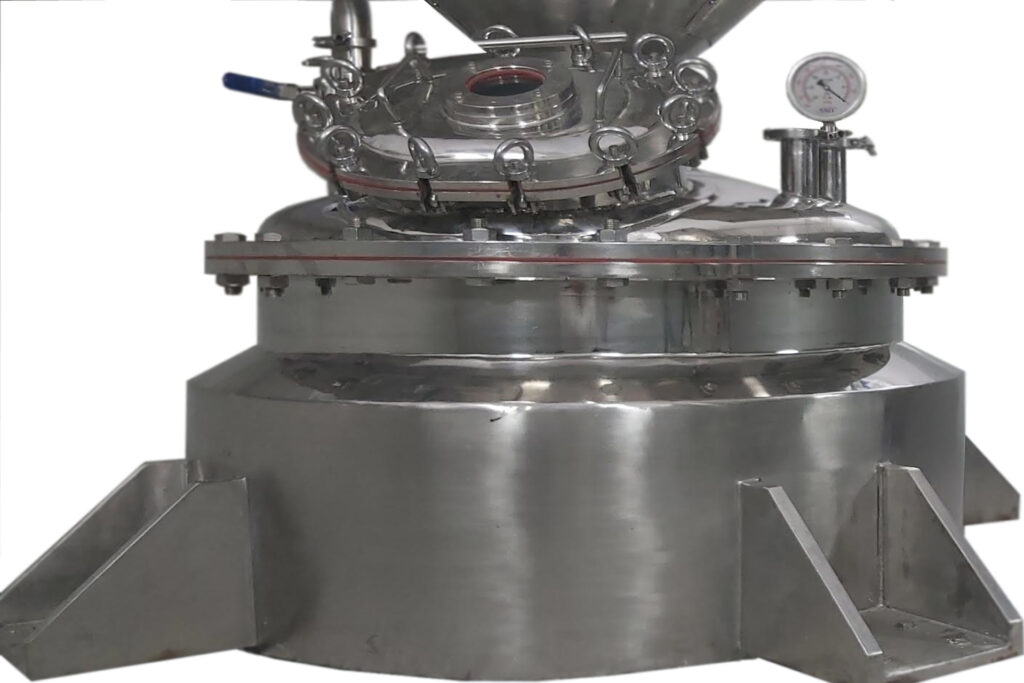

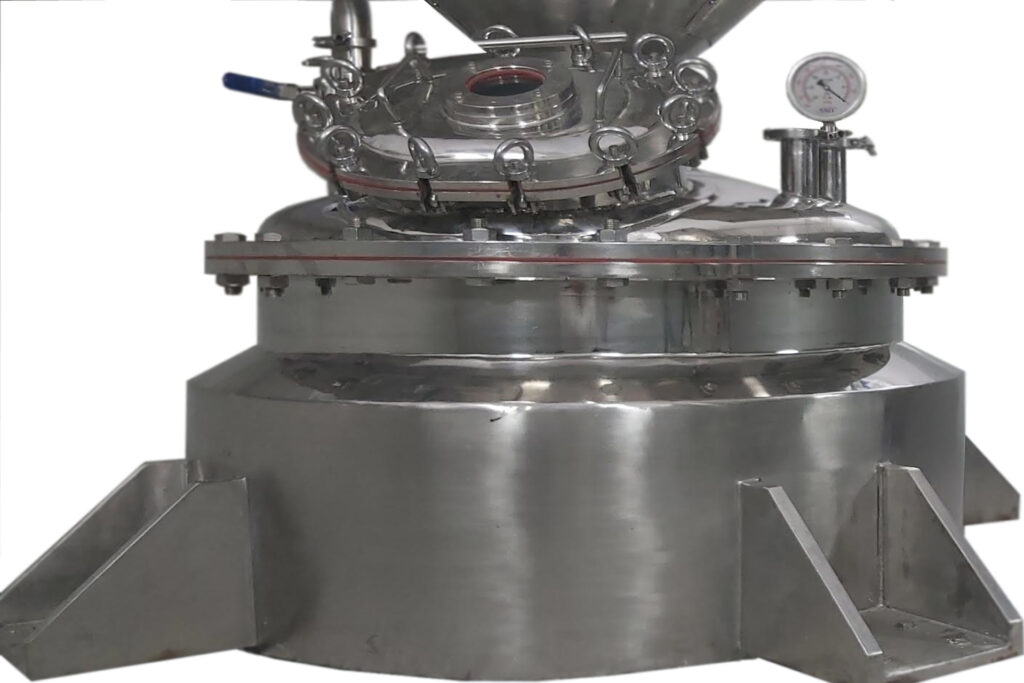

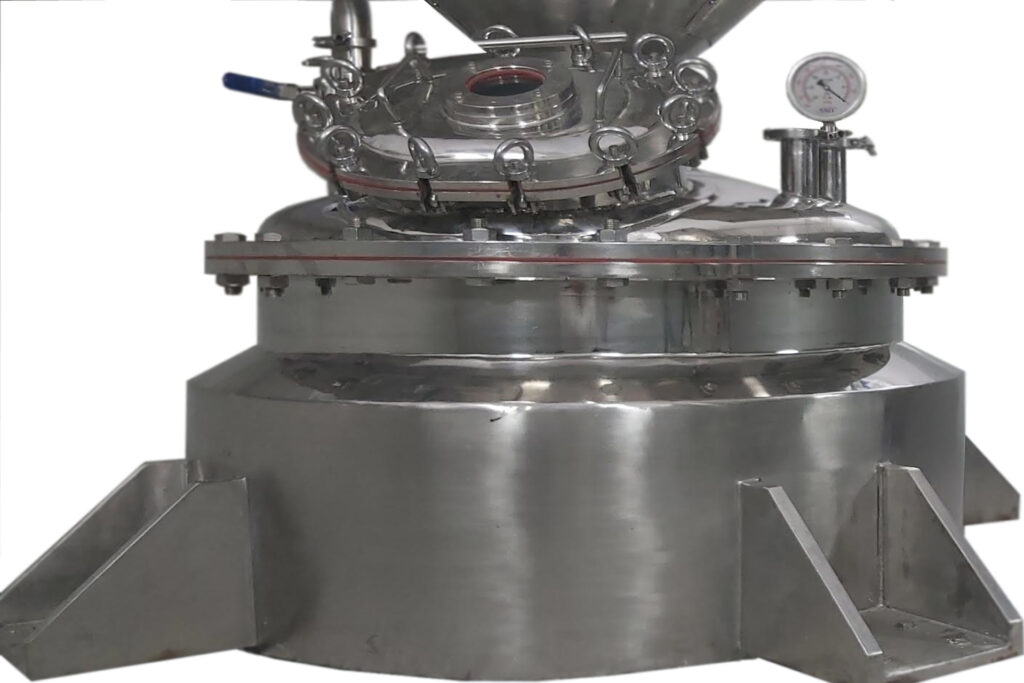

Contra rotary mixer

Contra Rotary mixer are using for mixing of high density product in pharmaceutical, chemical, cosmetic and food processing industry.(Gelatin cooking, tooth paste making etc.)

Technical specifications

- The mixer is so designed to high vacuum applied during the process.

- Contra rotary mixers are provided with double motion agitator blades that rotate in opposite directions to each other.

- Contra mixers are provided with a jacket to cool or heat as per application. The vessel has a shell of suitable thickness with a torispherical bottom and top disc.

- The vessel have a jacketed with stiffeners for suitable steam pressure.

- The jacket have insulated with glass wool.

- The vessel shall be suitable for 600 to 700 mm of Hg vacuum and internal pressure of 3 Kg / cm2.

- Both Motor drives with VFD by electrical Control Panel.

- All contact parts are made out of SS 316 and non-contact parts are made out of SS 304 and MS with SS 304 cladded.

- Digital temperature sensor display provided on the control panel, indicate of product and jacket temperature.

- Tank volume capacity is design as per water density.

- All contact parts of the machine are mirror finish and all non-contact parts are matt finish.

Model

- Machines with capacities from 50 liters to 1500 liters are made, and also produce lab models.

Salient features

- Material discharge from bottom flush bottom Y valve.

- Main hole with sight glass.

- Anchor and paddle blade speed control by electrical panel

- Jacket and product temperature control by digital temperature control sensor.

- Both the sets of blades intermesh with each other and rotate in clockwise and anti-clockwise direction. So high viscos material proper mixing during the process.

Electrical control panel

- Following function available on the control panel board.

- Main supply rotary switch

- R Y B indication

- Both motor start stop push button

- Both motor speed variable ports

- Digital temperature control display(Product and Jacket)

- Emergency stop switch

- Cooling fan for the inside panel